Donald Engineering: Your Strategic Partner for Custom Solutions

At Donald Engineering, Innovation Runs Deep. From simple tasks to the most complex and demanding motion control challenges, our experience and expertise shine. We develop custom solutions for our customers through the use of our in-house machining and electrical capabilities and expertise, as well as partnerships with our vendors.

For over 50 years our tailor-made products and solutions have provided positive outcomes for those we serve. Check out examples of past projects below and Contact Us today to discuss what we can do for you.

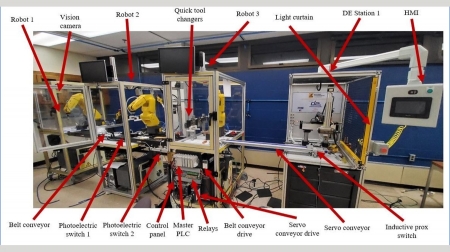

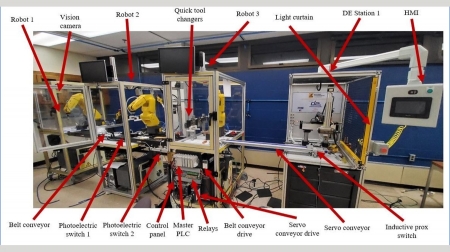

Michigan Technical University Mechatronics Lab

With an increase in smart technology, IoT, and other changes in manufacturing, our industry is seeing employment needs change quickly. To help keep up with this, the world of secondary education is starting to combine technology and engineering into one degree: Mechatronics. This multidisciplinary degree combines mechanical and electrical engineering with robotics, software, and computational hardware for a comprehensive and well-rounded background with current industry knowledge.

With an increase in smart technology, IoT, and other changes in manufacturing, our industry is seeing employment needs change quickly. To help keep up with this, the world of secondary education is starting to combine technology and engineering into one degree: Mechatronics. This multidisciplinary degree combines mechanical and electrical engineering with robotics, software, and computational hardware for a comprehensive and well-rounded background with current industry knowledge.

Donald Engineering has donated several interactive units to the Mechatronics Lab, an on-campus lab that will allow students the opportunity to work with programming, automation, part recognition, and implementation. The units Donald Engineering has provided to the Mechatronics lab include:

- Grip force and position sensor technology

- Two 3-axis robotic pneumatic platforms with HMIs control.

- Automatic tool changing station for multiple robotic end-of-arm tooling

- Belt-drive linear axis system for force position and overhung load and vibration analysis

- Collaborative end-of-arm tooling system kits and obstruction monitors

- Hydraulic closed-loop pump stand for understanding hydraulic pump technology

- PID motion controller and PI proportional pneumatic pressure control

- Control reliable machine safety equipment

This program and

DE's participation wouldn't be possible without the support of our customers and help from our vendors. We are honored to be in a position to give back to and support the next generation of engineers. Thank you to

Continental Hydraulics,

Ross Controls,

Schunk,

Clippard,

Oilgear, and

Milwaukee Cylinder for being strong supporters of this program.

Part Validation: A Differential Pressure Test

One of Donald Engineering's long-time customers wanted to advance their part validation capabilities and incorporate IOT solutions into their manufacturing and product test process. Our Technical Sales Rep, Mechanical Tech Engineer, and our Applications Engineering Team collaborated to provide a new (and the best) Differential Pressure Test solution to test fabricated liquid and gas pressure vessels that are welded together and intended to withstand extremely high-pressure capacities. By utilizing controlled compressed air and very sensitive sensors this new process uses a confirmed good part for pressure reference to test against a newly fabricated part. A PLC then allows for the test results to be sent to the customer's cloud for process analysis and batch recording.

One of Donald Engineering's long-time customers wanted to advance their part validation capabilities and incorporate IOT solutions into their manufacturing and product test process. Our Technical Sales Rep, Mechanical Tech Engineer, and our Applications Engineering Team collaborated to provide a new (and the best) Differential Pressure Test solution to test fabricated liquid and gas pressure vessels that are welded together and intended to withstand extremely high-pressure capacities. By utilizing controlled compressed air and very sensitive sensors this new process uses a confirmed good part for pressure reference to test against a newly fabricated part. A PLC then allows for the test results to be sent to the customer's cloud for process analysis and batch recording.

Check out the full story Here!

Ford Sniff Tester

When Ford reached out to Donald Engineering looking for a custom built validation test piece, DE delivered with a power air sampling unit incorporating products from Clippard and Divelbiss, showcasing DE's custom machining and fabrication capabilities.

When Ford reached out to Donald Engineering looking for a custom built validation test piece, DE delivered with a power air sampling unit incorporating products from Clippard and Divelbiss, showcasing DE's custom machining and fabrication capabilities.

Custom Marine PLC Kit

To open and close doors, sunroofs, and hatches in applications specific to the marine industry, Donald Engineering developed a water-resistant and shockproof Programmable Logic Controller to withstand harsh vibration and moist atmospheric conditions. The PLC is equipped with multiple digital inputs and outputs and can be completely customized using simple ladder logic. This unit is capable of not only opening and closing a door, window or sunroof but also monitoring open and closed positions as well as performing safety checks to prevent injuries before closing.

To open and close doors, sunroofs, and hatches in applications specific to the marine industry, Donald Engineering developed a water-resistant and shockproof Programmable Logic Controller to withstand harsh vibration and moist atmospheric conditions. The PLC is equipped with multiple digital inputs and outputs and can be completely customized using simple ladder logic. This unit is capable of not only opening and closing a door, window or sunroof but also monitoring open and closed positions as well as performing safety checks to prevent injuries before closing.

Donald Engineering possesses the ability to expand this PLC with analog inputs and outputs as well as wireless communications in which the unit can notify anyone or anything of use, task completion, or system error via phone line.

Marine Air Compressor Assembly

To meet the specific application needs of the marine industry, Donald Engineering developed an air compressor assembly for air horn operation and other accessories on board such as the sunroof. This compact unit minimizes wasted space on the vessel and is designed to withstand the harsh operating conditions of the marine environment.

To meet the specific application needs of the marine industry, Donald Engineering developed an air compressor assembly for air horn operation and other accessories on board such as the sunroof. This compact unit minimizes wasted space on the vessel and is designed to withstand the harsh operating conditions of the marine environment.

With an increase in smart technology, IoT, and other changes in manufacturing, our industry is seeing employment needs change quickly. To help keep up with this, the world of secondary education is starting to combine technology and engineering into one degree: Mechatronics. This multidisciplinary degree combines mechanical and electrical engineering with robotics, software, and computational hardware for a comprehensive and well-rounded background with current industry knowledge.

With an increase in smart technology, IoT, and other changes in manufacturing, our industry is seeing employment needs change quickly. To help keep up with this, the world of secondary education is starting to combine technology and engineering into one degree: Mechatronics. This multidisciplinary degree combines mechanical and electrical engineering with robotics, software, and computational hardware for a comprehensive and well-rounded background with current industry knowledge.  One of Donald Engineering's long-time customers wanted to advance their part validation capabilities and incorporate IOT solutions into their manufacturing and product test process. Our Technical Sales Rep, Mechanical Tech Engineer, and our Applications Engineering Team collaborated to provide a new (and the best) Differential Pressure Test solution to test fabricated liquid and gas pressure vessels that are welded together and intended to withstand extremely high-pressure capacities. By utilizing controlled compressed air and very sensitive sensors this new process uses a confirmed good part for pressure reference to test against a newly fabricated part. A PLC then allows for the test results to be sent to the customer's cloud for process analysis and batch recording.

One of Donald Engineering's long-time customers wanted to advance their part validation capabilities and incorporate IOT solutions into their manufacturing and product test process. Our Technical Sales Rep, Mechanical Tech Engineer, and our Applications Engineering Team collaborated to provide a new (and the best) Differential Pressure Test solution to test fabricated liquid and gas pressure vessels that are welded together and intended to withstand extremely high-pressure capacities. By utilizing controlled compressed air and very sensitive sensors this new process uses a confirmed good part for pressure reference to test against a newly fabricated part. A PLC then allows for the test results to be sent to the customer's cloud for process analysis and batch recording. When Ford reached out to Donald Engineering looking for a custom built validation test piece, DE delivered with a power air sampling unit incorporating products from Clippard and Divelbiss, showcasing DE's custom machining and fabrication capabilities.

When Ford reached out to Donald Engineering looking for a custom built validation test piece, DE delivered with a power air sampling unit incorporating products from Clippard and Divelbiss, showcasing DE's custom machining and fabrication capabilities. To open and close doors, sunroofs, and hatches in applications specific to the marine industry, Donald Engineering developed a water-resistant and shockproof Programmable Logic Controller to withstand harsh vibration and moist atmospheric conditions. The PLC is equipped with multiple digital inputs and outputs and can be completely customized using simple ladder logic. This unit is capable of not only opening and closing a door, window or sunroof but also monitoring open and closed positions as well as performing safety checks to prevent injuries before closing.

To open and close doors, sunroofs, and hatches in applications specific to the marine industry, Donald Engineering developed a water-resistant and shockproof Programmable Logic Controller to withstand harsh vibration and moist atmospheric conditions. The PLC is equipped with multiple digital inputs and outputs and can be completely customized using simple ladder logic. This unit is capable of not only opening and closing a door, window or sunroof but also monitoring open and closed positions as well as performing safety checks to prevent injuries before closing. To meet the specific application needs of the marine industry, Donald Engineering developed an air compressor assembly for air horn operation and other accessories on board such as the sunroof. This compact unit minimizes wasted space on the vessel and is designed to withstand the harsh operating conditions of the marine environment.

To meet the specific application needs of the marine industry, Donald Engineering developed an air compressor assembly for air horn operation and other accessories on board such as the sunroof. This compact unit minimizes wasted space on the vessel and is designed to withstand the harsh operating conditions of the marine environment. Our automotive customer was in need of a new solution to test parts and study how they behaved while being crushed in various ways. Donald Engineering helped to create a custom solution with a variety of components and vendor-partner resources. The Crush Test application is a hydraulic press that allows a piece, of substantial and unique size, to fit in between a plate and a hydraulic cylinder press. Load cells, position transducers, and multiple cameras are used to capture forces and locations, revealing part material fluctuations and failures points.

Our automotive customer was in need of a new solution to test parts and study how they behaved while being crushed in various ways. Donald Engineering helped to create a custom solution with a variety of components and vendor-partner resources. The Crush Test application is a hydraulic press that allows a piece, of substantial and unique size, to fit in between a plate and a hydraulic cylinder press. Load cells, position transducers, and multiple cameras are used to capture forces and locations, revealing part material fluctuations and failures points. Donald Engineering's applications team delivered quick solutions with this Pick-n-Place for Aluminum Extrusion featuring:

Donald Engineering's applications team delivered quick solutions with this Pick-n-Place for Aluminum Extrusion featuring: When customers are in need of a custom filter cart, Donald Engineering delivers with solutions tailored to their exact needs and specifications. Our custom filter carts help to lower our customer's total cost of ownership by mitigating contamination of their hydraulic systems and equipment.

When customers are in need of a custom filter cart, Donald Engineering delivers with solutions tailored to their exact needs and specifications. Our custom filter carts help to lower our customer's total cost of ownership by mitigating contamination of their hydraulic systems and equipment.  As trusted experts in Machine Safety, Donald Engineering regularly works to provide custom machine guarding solutions for our customers. After carefully analyzing your unique application, we'll deliver a tailor-made system that ensures maximum safety for your employees and your equipment.

As trusted experts in Machine Safety, Donald Engineering regularly works to provide custom machine guarding solutions for our customers. After carefully analyzing your unique application, we'll deliver a tailor-made system that ensures maximum safety for your employees and your equipment. Donald Engineering regularly designs and builds custom manifolds for our customers' unique hydraulic and pneumatic systems. Pairing our expertise with the best components on the market, we'll design and develop a specialized solution for your unique application.

Donald Engineering regularly designs and builds custom manifolds for our customers' unique hydraulic and pneumatic systems. Pairing our expertise with the best components on the market, we'll design and develop a specialized solution for your unique application.  To equip customers with high-quality vacuum pump systems, Donald Engineering regularly produces custom-built units that are both mobile and suited for use in a wide variety of applications. This particular pump can plug into 110 vac or 220 vac and was built with an onboard filter and vacuum gauge.

To equip customers with high-quality vacuum pump systems, Donald Engineering regularly produces custom-built units that are both mobile and suited for use in a wide variety of applications. This particular pump can plug into 110 vac or 220 vac and was built with an onboard filter and vacuum gauge.