Strategies and Solutions for Hydraulic Safety

When designing a Hydraulic System, there are many factors to consider. Speed, Pressure, Horsepower, Valves, System Design...the list goes on! While these factors are important to consider, other important questions are often overlooked. Questions such as:

- How to properly isolate and dissipate stored energy from an accumulator? Can it be done automatically?

- How to remove system energy when an operator is inside the light curtain in a safe and reliable way?

- How to remove stored energy from a system and verify that it has dissipated?

- What effect does gravity affect the situation? Has stored energy been introduced because of gravity?

- What valving is required to keep a load from falling?

We'll work with you to cover all the bases, mitigating the risk of hydraulic safety accidents and ensuring a lower cost of ownership for your investments.

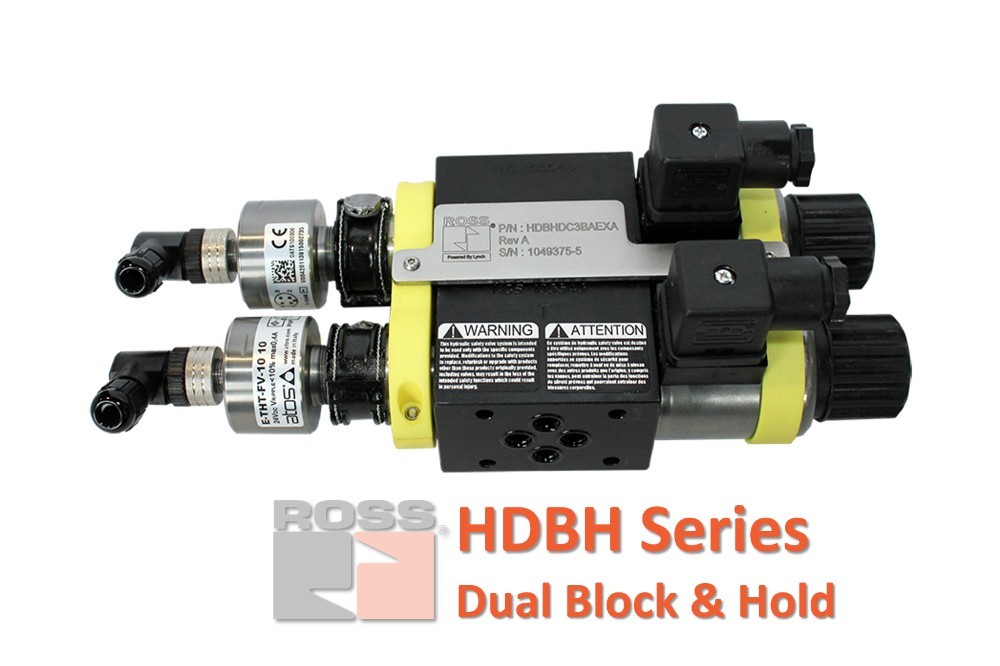

Dual Monitored Hydraulic valve packages for control reliable energy control

This D05 dual monitored valve package from Continental Hydraulic control reliably blocks pressure and flow. Mounted after an accumulator, stored energy is blocked from harming equipment and operators. This package is integrated into the larger electrical safety system. Contact us for application assistance.

This D05 dual monitored valve package from Continental Hydraulic control reliably blocks pressure and flow. Mounted after an accumulator, stored energy is blocked from harming equipment and operators. This package is integrated into the larger electrical safety system. Contact us for application assistance.

We offer packages size D03-D10 and also in Din Logic formats. Flow ranges from 6 gpm through 200+.

Single monitored valves for integration in series in larger applications

Single Monitored valves, in series are sometimes utilized in larger machines. This is often found in European equipment as European safety standards push designers to approach system design differently. We have experience in this type of thought process as well. If you are shipping a machine to Europe, let us assist you in your safety system design. We have the components and expertise to complete the project.

Single Monitored valves, in series are sometimes utilized in larger machines. This is often found in European equipment as European safety standards push designers to approach system design differently. We have experience in this type of thought process as well. If you are shipping a machine to Europe, let us assist you in your safety system design. We have the components and expertise to complete the project.

This D05 dual monitored valve package from Continental Hydraulic control reliably blocks pressure and flow. Mounted after an accumulator, stored energy is blocked from harming equipment and operators. This package is integrated into the larger electrical safety system. Contact us for application assistance.

This D05 dual monitored valve package from Continental Hydraulic control reliably blocks pressure and flow. Mounted after an accumulator, stored energy is blocked from harming equipment and operators. This package is integrated into the larger electrical safety system. Contact us for application assistance. Single Monitored valves, in series are sometimes utilized in larger machines. This is often found in European equipment as European safety standards push designers to approach system design differently. We have experience in this type of thought process as well. If you are shipping a machine to Europe, let us assist you in your safety system design. We have the components and expertise to complete the project.

Single Monitored valves, in series are sometimes utilized in larger machines. This is often found in European equipment as European safety standards push designers to approach system design differently. We have experience in this type of thought process as well. If you are shipping a machine to Europe, let us assist you in your safety system design. We have the components and expertise to complete the project.